I’m starting to get back into the swing of things working on the car. I’m still pretty busy with stuff most weekends but I’m being better about taking a few hours here and there to work on the car. Today was a good work day — I spent about five hours working on the car, and actually managed to make a good bit of progress. Its been two months of frustration getting the body fitting and bolted down, but I’ve finally gotten it as close as its going to get, and all the bolts are in.

I also got the front elephant ears installed.

I started off the day installing the driver’s side door. This entailed a lot more time than it should’ve — one of the square nuts that holds the hinge to the chassis was missing. After a half hour of poking around, I realized it’d fallen down and gotten caught up between the chassis and the body.

The doors don’t fit perfectly, and need some grinding to fit into the openings in the body, but they’re good enough for now. I want to trim the panels as little as I can get away with prior to getting the body work done and the car painted.

It took me another hour of futzing with the body bolts on the passenger side to get the front pair of side bolts in, but I eventually got them tightened down.

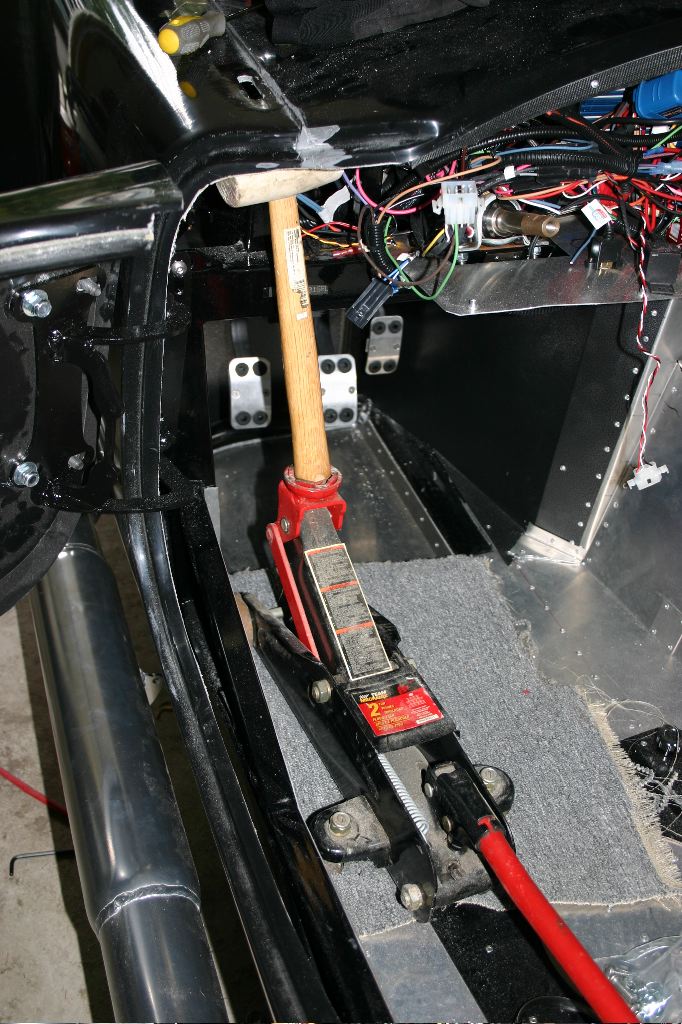

The driver’s side bolts were a lot more of a problem. After an hour of trying to force them to fit, I realized the body was just sitting too low on the driver’s side of the car. Aimee helped me by trying to lift the body up some, but the body is heavy enough, and under enough tension, that I still couldn’t get the bolts in.

After some troubleshooting, I eventually came up with the idea of using a small jack and my rubber mallet to lift that corner of the body up the half inch that I needed to get the bolts in. It took some adjustment, but the bolts went right in. Once that was done, I could tighten back up the bolts in the nose of the car, and the body was entirely bolted down. The driver’s door needed adjustment at that point because the body is higher now on the driver’s side.

With the doors on and rollbars in, it really is starting to look like a car.

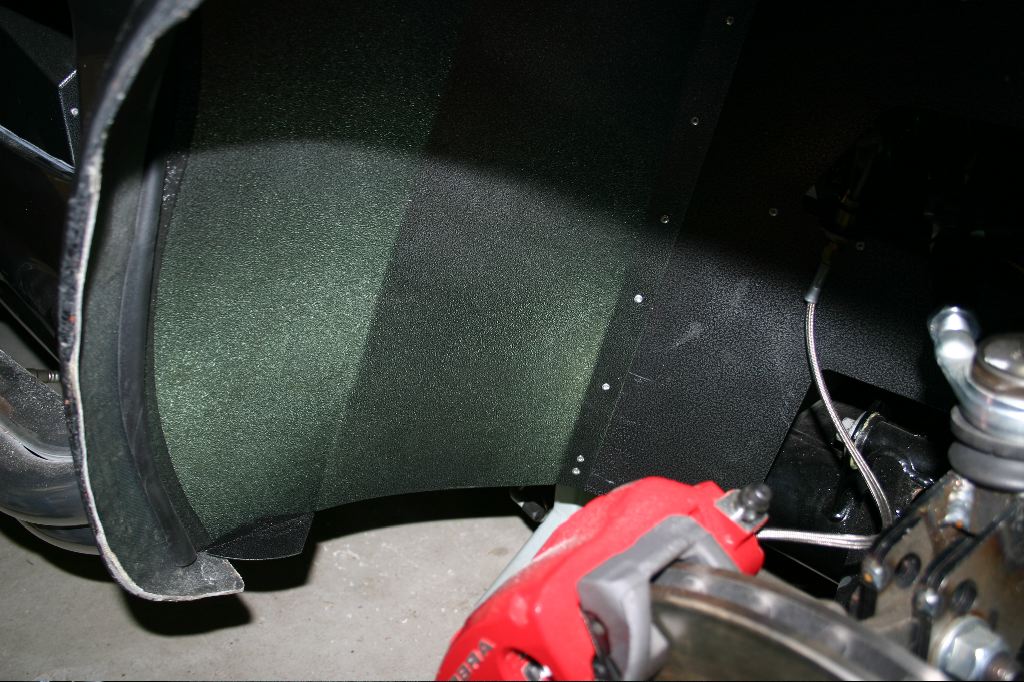

I took a break for a couple hours at that point — it’d gotten pretty hot in the garage. Later in the afternoon, I decided to get the elephant ears installed. These are two panels that go to the rear of the front wheel wells, to keep water out of the cockpit.

It took a lot of pushing and pulling to get them in — they actually hold the body out, so they’re under compression when they are installed.

I didn’t use any silicone with these panels — I have to take them back out to take the body off to get painted and I didn’t want to have to clean them up at that point.

The body is held out farther which leaves a fairly good gap around the side pipes.

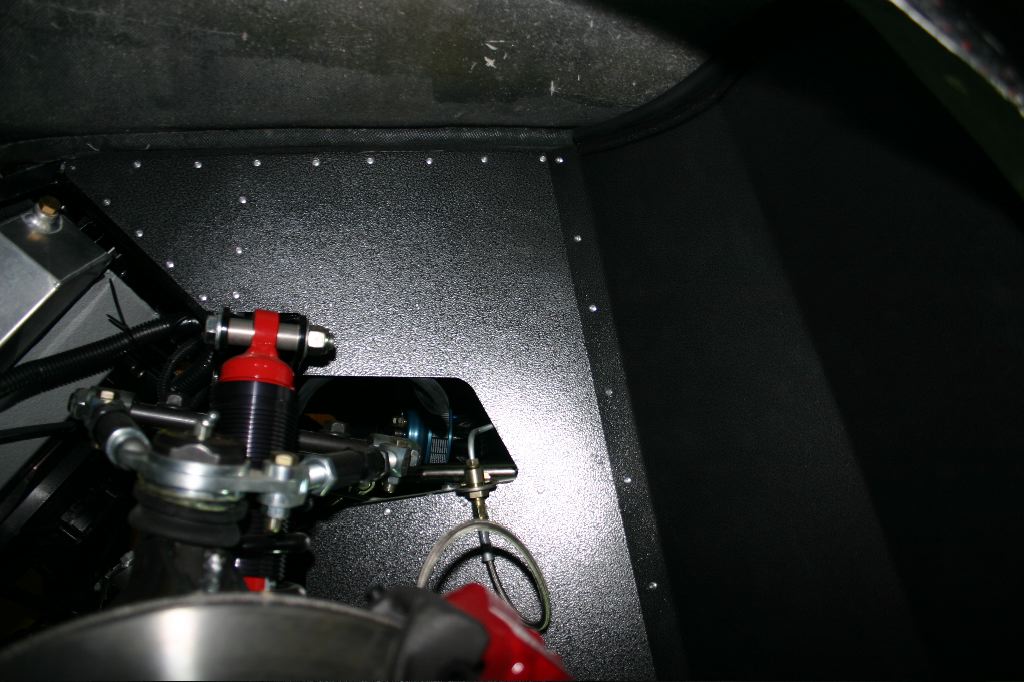

The passenger side was a bigger issue — the heater ducting runs through that area, and I had to cut an opening in the panel on the passenger side to allow the 3″ hose to pass through. Because there’s a few compound angles involved, getting the shape of the opening was a matter of trial and error.

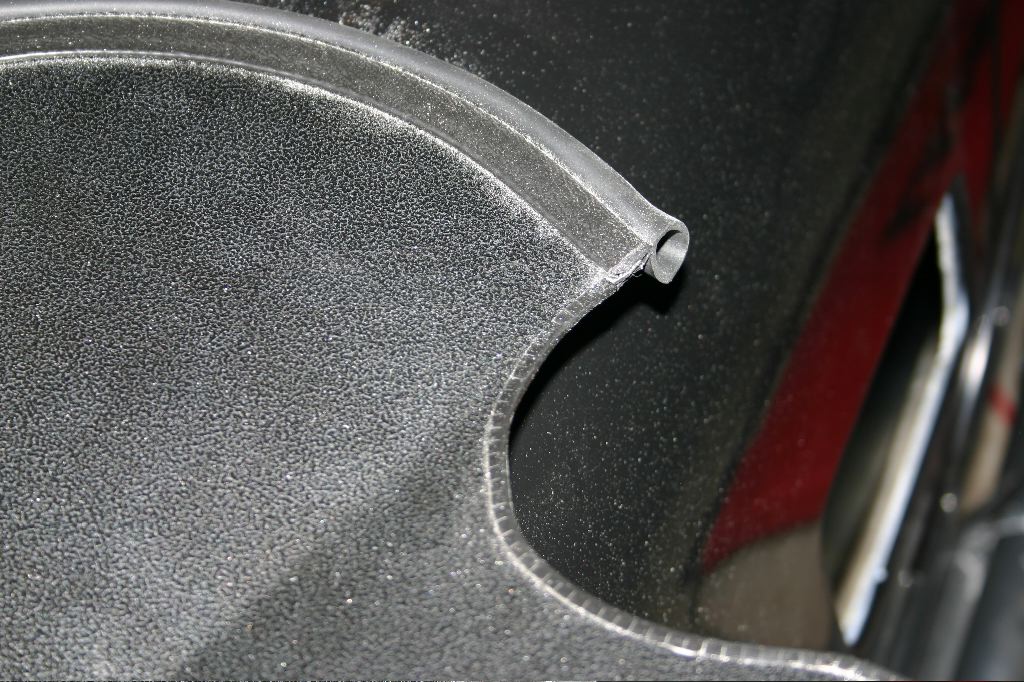

The rubber bulb seal goes (as it did on the driver’s panel) around the edges that contact the body.

Some adhesive-lined plastic grommet was run along the cut edge to ensure the hose wasn’t cut by the sheet metal.

With the panel installed, the hose passes nicely through from the wheel well into the engine bay. The blower is immediately on the other side of the panel.

The panel holds the body out slightly more, which gives a little more gap around the side pipe. This is still too tight, and I think it’ll have to be trimmed a bit wider when the body is painted.

I started to look at installing the rears, but I was literally covered in metal shavings from trimming the panel in the front and decided to call it quits for the day. I’ll try to get them installed tomorrow or another evening this week. The next step is the windshield, hopefully next weekend.